#MM-07, #MM-08 from

Review by Terry Ashley

There are two sizes initially with a larger version to follow to allow the formation of fuel tank sized items such as those on the T-55.

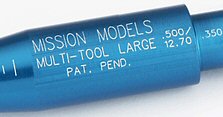

The tools are self contained with no additional parts and the first two are Small (#MM-07) and Large (#MM-08) which are in aluminium with an anodised bronze and blue finish respectively and feature engraved calibrations in both metric and inches on the ‘head’ and six ‘steps’ for different sized curves. The small end section is in hardened steel as the aluminium may bend at this small diameter, a nice touch.

The engraved calibrations on the

Small tool are; .375in/9.53mm, .325in/8.26mm, .275in/6.99mm, .225in/5.72mm,

.175in/4.45mm, .100in/2.54mm, .047in/1.20mm while those on the Large tool

are; .500in/12.70mm, .350in/8.89mm, .300in/7.62mm, .250in/6.35mm, .200in/5.08mm,

.125in/3.18mm, .063/1.60, to cover most sizes you may want.

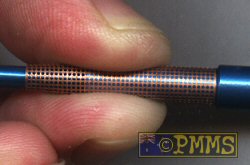

The front section of the tool is cone shaped to allow bending conical shaped

parts while the rounded tip is designed to use a burnishing tool for applying

dry transfers.The tool is very easy to use by simple placing the part to

be bent over the appropriate sized section and rolling between the fingers

until the required bend is achieved, by placing the part hard up against the ‘step’ of

the next larger section will ensure the part will bent perfectly square.

To aid in this process it is best to ‘anneal’ larger parts by

quickly running the parts through a candle or gas stove top flame just briefly

enough for the part to turn red and allowed to cool naturally (do not dip into

water).

The appropriate care should be taken when using naked flames and in handling

hot parts.

Any sized part can be bent either to a U shape or full circle and by selecting a slightly smaller part of the tool will allow a degree of over bend which will help in getting a good join on full circle parts.

Parts with only small curves can also be bent on the Multi-tool by placing the part over the tool and applying slight finger pressure for an even bend such as the machine gun shields on the Sd.Kfz.250 or 251 halftrack.

While designed for etched parts the tool can also be used to bend wire of different thicknesses to form ‘U’ shaped or full discs in basically the same manner as for etched parts to add another use and as mentioned the rounded point is used for burnishing dry transfers and the anodised finish aids in this.

Conclusion:

Overall the tools are easy to handle sitting comfortably in the hand while

rolling the parts being bent as well as the additional functions of bending

wire and

dry transfer application for another useful tool for the toolbox.

They should find many uses in bending items such as exhaust covers, flash suppressors on flak guns, the cooling jackets on .50 cal MGs plus many other uses only limited by your imagination.

Highly recommended.

Thanks to Jon from Mission Models for the Multi-Tool samples.

Page created 4 September 2004